More Important Than You Think

Critical to Pavement Success

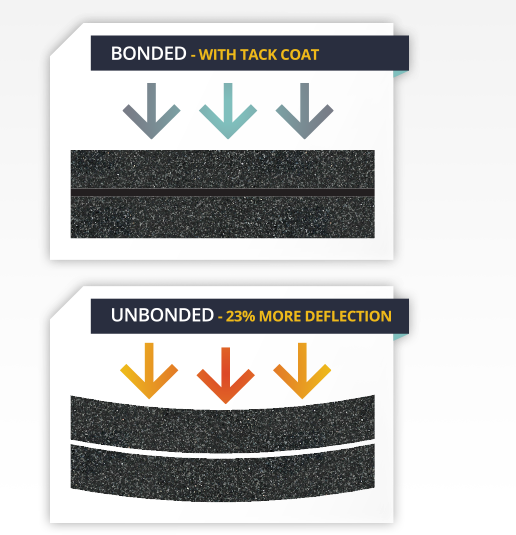

Tack Coat, more accurately called bond coat, ensures proper bonding between old and new layers of asphalt. When properly bonded, the cross section of road will act as a single unit, ensuring vital structural integrity and helping prevent many of the major problems associated with road failure.

When Applied Correctly, Bond Coat

- Helps create a monolithic structure

- Significantly reduces delamination

- Improves fatigue life

- Reduces rutting and shoving

- Facilitates better compaction

More Bond Coat, Better Roads

In 2013, NCAT had a premature failure on the test track. Forensics revealed that insufficient bond coat was a significant factor, even though the rate and quality of bond coat was considered ideal. Laboratory testing showed that twice the previously recommended amount was needed to optimize bond strength.

What’s Your Role in Preventing Road Failure?

Contractor Proper Application is Crucial

- Bid Appropriately: Ensure your bid accounts for the proper amount of bond coat.

- Apply: Bond Coat should be applied to all surfaces, including milled surfaces, and in all conditions. Spray uniformly to transverse, longitudinal, vertical surfaces at proper rates. All surfaces. Everytime.

- Re-Apply: The Asphalt Institute recommends you re-tack when in doubt and especially if significant tracking or contamination occurs.

- Right equipment: Make sure distributors are clean, and that nozzles are correct size and are set at the proper angle. Ensure correct bar height and triple overlapping spray pattern.

- Calibrate and check the distributor to assure proper application rate

Agency Incentive and Inspect to Ensure Success

- Spec: Include bond coat in your spec as a pay item. Research finds that states with bond coat problems tend to treat bond coating as incidental, rather than a separate pay item.

- Inspect: Require bond coat inspection and inspect every time. Your road depends on it.

- Ensure Success: If you’re not specing bond coat as a pay item, and inspecting properly, you may be incentivizing road failure.

- Collaborate: Work with industry contractors and suppliers to get the best performance available

Supplier

- Expect: Improved standards and new research are changing industry practices. Expect the highest quality emulsions.

- Deliver: Consistent product

- Monitor: Product performance via jobsite visits or customer feedback